Why Choose Hastelloy Fabricators for Corrosion-Resistant Solutions?

When it comes to materials that can withstand extreme environments, Hastelloy is a top contender. Known for its exceptional corrosion resistance, heat stability, and mechanical strength, Hastelloy materials are widely used across industries like chemical processing, aerospace, and marine applications.

But here’s the key question: Why should you choose expert Hastelloy fabricators for your project? Whether you’re looking for Hastelloy C276 heat-resisting alloy rods, Hastelloy B2 round bars, or Hastelloy G30 components, understanding the benefits of working with specialized fabricators can make all the difference in ensuring durability and long-term performance.

What is Hastelloy and Why is it a Game-Changer?

Hastelloy, a nickel-based alloy, is renowned for its superior corrosion resistance, particularly in oxidation and stress corrosion cracking. Industries that require materials to withstand aggressive chemical environments or high temperatures frequently rely on Hastelloy alloys for their reliability and longevity.

Key Benefits of Hastelloy:

- Corrosion Resistance: Handles highly acidic and oxidizing environments.

- High-Temperature Strength: Performs exceptionally well under extreme heat.

- Versatility: Used in chemical plants, marine applications, and aerospace industries.

- Durability: Longer lifespan compared to stainless steel and other alloys.

💡 Pro Tip: If your industry deals with harsh conditions like chemical processing or marine exposure, choosing Hastelloy-based components can save you maintenance costs and downtime in the long run.

Which Type of Hastelloy is Right for Your Application?

| Hastelloy Grade | Key Features | Best Applications |

|---|---|---|

| Hastelloy C276 | Exceptional heat resistance, and corrosion protection in harsh environments | Heat exchangers, flue gas scrubbers, power plants |

| Hastelloy G30 | Superior resistance to oxidizing acids | Chemical processing, fertilizer plants |

| Hastelloy B2 | Strong resistance to hydrochloric acid and other aggressive chemicals | Aerospace, marine, and pollution control systems |

💡 Choosing the wrong Hastelloy grade can lead to inefficiency and reduced lifespan of your components. Working with expert Hastelloy fabricators ensures you get the right material tailored to your application.

Why Work with Professional Hastelloy Fabricators?

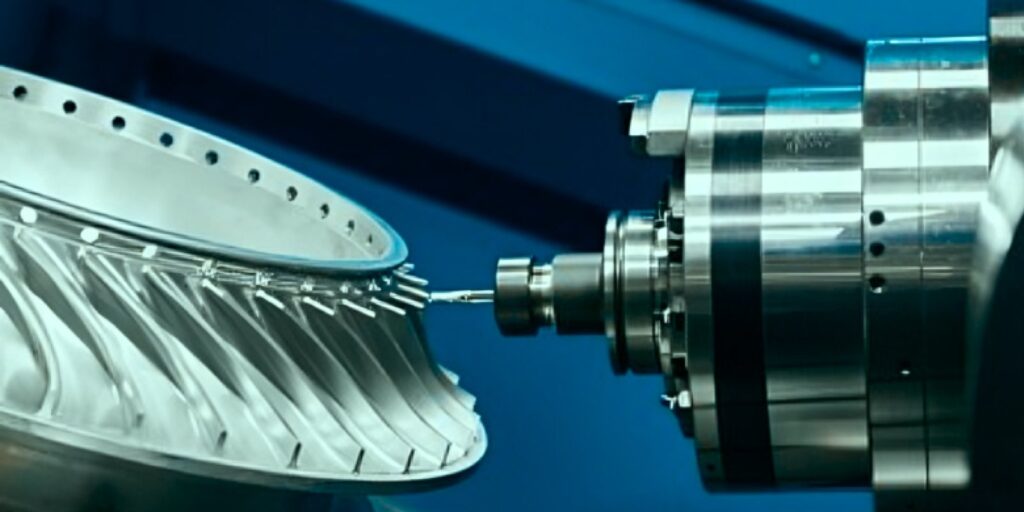

Fabricating Hastelloy alloys requires precision, expertise, and the right heat treatment and welding techniques, making experienced Hastelloy fabricators crucial for superior corrosion resistance.

1. Expert Welding and Fabrication Techniques

Hastelloy is tough, but improper welding can lead to cracking and performance issues. Professional fabricators use advanced techniques like:

- TIG Welding (GTAW): This ensures high-quality joints for durability.

- Precision Machining: Guarantees tight tolerances for industrial use.

2. Customized Solutions for Your Industry

Every project is unique. Hastelloy fabricators can customize components such as:

- Hastelloy C276 heat-resisting alloy rods for high-temperature applications.

- Hastelloy B2 round bars for corrosion-resistant structural support.

3. Cost-Efficient Manufacturing

💡 Did you know? Using a general fabricator instead of a specialist in Hastelloy alloys can lead to higher production costs due to wasted material and inefficiencies.

- Expert fabricators maximize material efficiency and reduce waste.

- Long-term savings with durable, low-maintenance nickel alloy components.

How to Choose the Right Hastelloy Fabricator?

Do They Specialize in Hastelloy?

Not all metal fabricators work with Hastelloy alloys. Seek those experienced in high-performance nickel alloys and who can provide references.

Do They Offer Customization?

Your project may require custom dimensions, shapes, or coatings, especially when using Hastelloy alloys for tailored solutions to fit your needs.

Do They Meet Industry Standards?

To ensure the high-quality production of Hastelloy alloys, check that the fabricator complies with ASTM, ASME, and ISO certifications.

Conclusion: Invest in the Best for Maximum Durability

When it comes to corrosion-resistant materials, Hastelloy is one of the most durable and high-performing alloys available. However, choosing the right Hastelloy fabricator is just as important as selecting the right material.

Need premium Hastelloy C276 rods, Hastelloy B2 round bars, or customized Hastelloy fabrication? Work with expert Hastelloy fabricators to ensure you get the best quality, long-lasting performance, and cost-effective solutions for your industry.

Ready to optimize your operations with corrosion-resistant Hastelloy components? Contact us today to get expert guidance and high-quality fabrication services!

FAQ's

Need Help?

We're Here for You!

Feel free to contact us any time. we will get back to you as soon as we can!

Ask Anything

Yes! Hastelloy alloys outperform stainless steel in acidic and high-temperature environments, making them ideal for chemical processing and marine applications.

Industries such as chemical processing, power plants, marine, aerospace, and oil & gas rely on Hastelloy alloys due to their durability and excellent corrosion resistance.

- Choose Hastelloy C276 for high heat resistance and oxidation protection.

- Choose Hastelloy B2 for handling hydrochloric acid and aggressive chemicals. For customized recommendations, always consult a Hastelloy fabricator.