How to Choose the Best Metal Manufacturers: Carbon Steel, Stainless Steel & Alloys

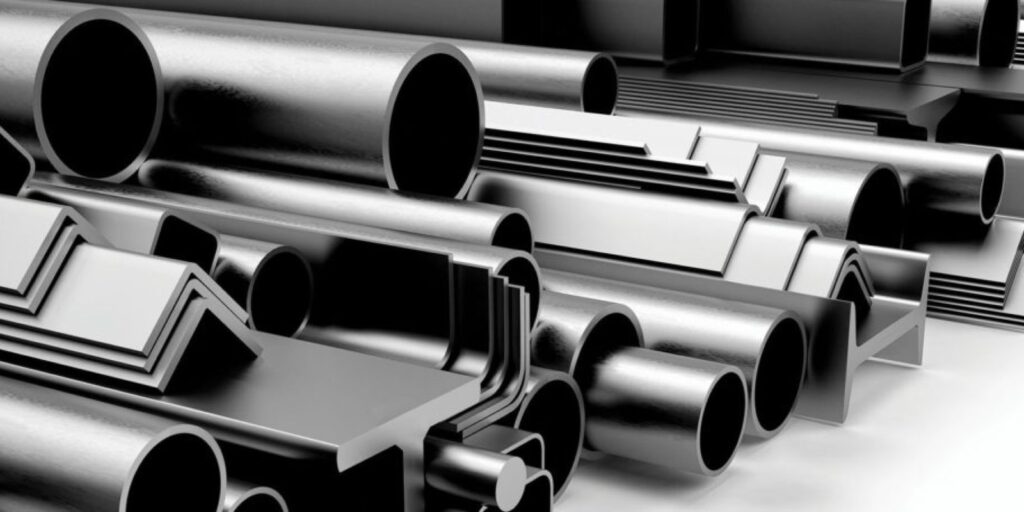

When selecting a metal manufacturer, the quality, reliability, and expertise of the supplier can significantly impact your project’s success. Whether you need carbon steel plates, stainless steel tubes, or high-performance nickel alloys, choosing the right manufacturer ensures durability, cost-effectiveness, and compliance with industry standards.

This guide will walk you through what to look for in a carbon steel plate manufacturer, stainless steel plate supplier, Hastelloy fabricator, and nickel alloy products provider, helping you make the best decision for your industrial applications.

👉 Looking for in-depth insights? Check out:

- How Carbon Steel Plate Manufacturers Ensure Top Quality

- How to Choose the Best Stainless Steel Plate Manufacturer for Your Needs

- Why Choose Hastelloy Fabricators for Corrosion-Resistant Solutions?

- Why Nickel Alloy Tubes and Forged Parts Are Perfect for High-Performance Applications

1. How to Identify a Reliable Carbon Steel Plate Manufacturer

Key Considerations:

- Material Quality: Does the manufacturer supply high-grade carbon steel that meets industry standards?

- Production Capabilities: Can they handle large-scale orders with precision cutting and customization?

- Certifications: Look for ISO, ASTM, and ASME compliance.

Why It Matters:

A reputable carbon steel plate supplier ensures that the material offers high tensile strength, excellent machinability, and corrosion resistance. This is crucial for applications in construction, shipbuilding, and heavy machinery.

📌 Pro Tip: Always check if the carbon steel plate company offers high carbon steel plates with custom thicknesses, as this impacts load-bearing capacity.

👉 Learn more: How Carbon Steel Plate Manufacturers Ensure Top Quality

2. Choosing the Right Stainless Steel Plate Manufacturer

What to Look for:

- Grade Variety: Ensure they supply 304, 316, and 430 stainless steel for different applications.

- Processing Options: Do they offer cut-to-size plates, polished surfaces, and precision laser cutting?

- Stainless Steel Plate Applications: Are they experienced in supplying materials for food processing, medical, and marine industries?

Why It Matters:

A high-quality stainless steel plate manufacturer provides corrosion-resistant, durable, and heat-resistant plates for industries like automotive, aerospace, and chemical processing.

📌 Pro Tip: Ask if the supplier also provides stainless steel tubes for piping solutions to match your project needs.

👉 Learn more: How to Choose the Best Stainless Steel Plate Manufacturer for Your Needs

3. Why Choose Hastelloy Fabricators for Corrosion-Resistant Solutions?

Key Considerations:

- Alloy Grades: Does the manufacturer offer Hastelloy C276, Hastelloy G30, and Hastelloy B2?

- Heat Resistance: Does the supplier provide heat-resisting alloy rods for high-temperature applications?

- Welding & Fabrication Expertise: Are they experienced in handling Hastelloy material without compromising its corrosion-resistant properties?

Why It Matters:

Hastelloy is used in chemical processing, power plants, and aerospace due to its superior corrosion resistance and heat endurance. Partnering with an experienced Hastelloy fabricator ensures long-lasting and durable components.

📌 Pro Tip: For extreme environments, Hastelloy C276 heat-resisting alloy rods offer the best protection against oxidation and corrosion.

👉 Learn more: Why Choose Hastelloy Fabricators for Corrosion-Resistant Solutions?

4. How to Select the Best Nickel Alloy Supplier

What to Consider:

- Product Range: Do they supply nickel alloy plates, tubes, and fittings for various applications?

- Precision Manufacturing: Are they skilled in nickel alloy plate rolling and producing forged nickel alloy parts?

- High-Performance Alloys: Do they specialize in high nickel alloy fittings for aerospace, marine, and industrial use?

Why It Matters:

Nickel alloys offer exceptional strength, corrosion resistance, and thermal stability, making them ideal for power plants, desalination plants, and defense applications.

📌 Pro Tip: When buying nickel alloy tubing, ensure it meets standards for pressure resistance and seamless construction.

👉 Learn more: Why Nickel Alloy Tubes and Forged Parts Are Perfect for High-Performance Applications

Final Checklist: How to Choose the Best Metal Manufacturer

| Factor | Carbon Steel | Stainless Steel | Hastelloy | Nickel Alloy |

|---|---|---|---|---|

| Material Quality | ✅ High-strength | ✅ Corrosion-resistant | ✅ Extreme durability | ✅ High-temperature resistance |

| Industry Certifications | ✅ ISO, ASTM, ASME | ✅ ASTM, ASME | ✅ API, NACE | ✅ ISO, ASTM |

| Custom Fabrication | ✅ Cutting, bending, welding | ✅ Polishing, laser cutting | ✅ Precision fabrication | ✅ Forging, plate rolling |

| Common Applications | ✅ Construction, shipbuilding | ✅ Medical, food processing | ✅ Chemical, aerospace | ✅ Power plants, aerospace |

Conclusion: Invest in the Right Metal Supplier for Your Needs

Selecting a high-quality metal manufacturer is crucial for ensuring the durability, efficiency, and performance of your projects. Whether you’re in need of carbon steel plates, stainless steel tubes, Hastelloy fabrications, or nickel alloy piping products, working with a trusted supplier guarantees long-term reliability and cost savings.

Want expert recommendations? Explore these related guides:

- How Carbon Steel Plate Manufacturers Ensure Top Quality

- How to Choose the Best Stainless Steel Plate Manufacturer for Your Needs

- Why Choose Hastelloy Fabricators for Corrosion-Resistant Solutions?

- Why Nickel Alloy Tubes and Forged Parts Are Perfect for High-Performance Applications

Need a quote for high-quality metal products? Contact us today for customised solutions tailored to your project requirements!

FAQ's

Need Help?

We're Here for You!

Feel free to contact us any time. we will get back to you as soon as we can!

Ask Anything

Carbon steel materials, known for their high strength and durability, are widely used in construction, shipbuilding, and heavy machinery.

Stainless steel, with its high corrosion resistance and mechanical strength, is ideal for food processing, automotive, and chemical industries, showcasing the benefits of alloy content.

Hastelloy, with its superior corrosion resistance, is ideal for chemical plants and heat exchangers, outperforming even stainless steels in acidic environments.

Nickel alloy tubing provides exceptional strength, thermal resistance, and corrosion protection, making it essential for power plants, aerospace, and industrial piping systems utilizing carbon steel materials.