Exploring Stainless Steel Tube and Pipe Fittings for Industries

Stainless steel is a fundamental material in industries that demand exceptional strength, durability, and resistance to corrosion. Stainless steel tube fittings and pipe fittings are essential components in fluid and gas transportation systems across industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals.

Stainless steel is a fundamental material in industries that demand exceptional strength, durability, and resistance to corrosion. Stainless steel tube fittings and pipe fittings are essential components in fluid and gas transportation systems across industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals.

At Om Steel, we provide a wide range of high-quality stainless steel fittings, including stainless steel pipe fittings and forged fittings, designed to meet the toughest industrial requirements. This guide examines the various types of stainless steel fittings, their applications, and their key benefits, highlighting why they are crucial for modern industrial systems.

Why Stainless Steel?

Stainless steel is a versatile alloy known for its exceptional mechanical and chemical properties, including good corrosion resistance. This material’s unique combination of strength and resistance to corrosion makes it ideal for industrial environments.

Key Properties:

- Corrosion Resistance: Resists rust and chemical damage, even in harsh environments.

- Durability: High strength-to-weight ratio ensures long-term performance.

- Heat Resistance: Performs reliably in extreme temperature conditions.

- Hygiene: Non-porous and easy to clean, suitable for sanitary applications.

Types of Stainless Steel Fittings

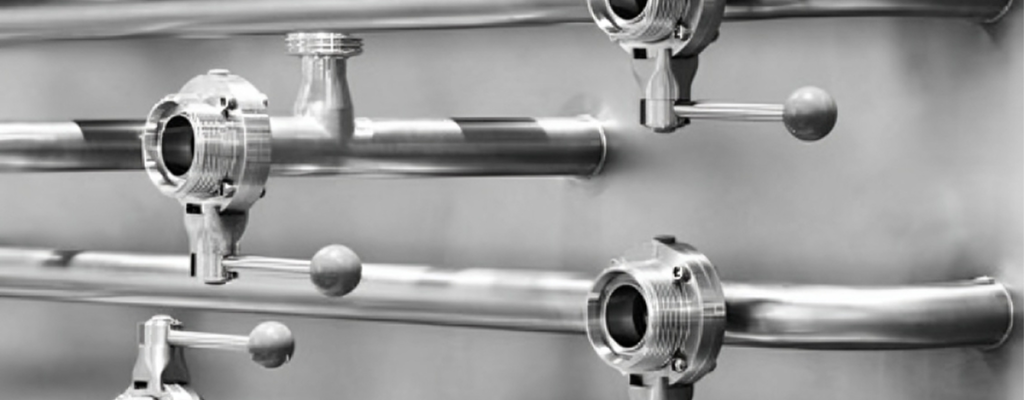

1. Stainless Steel Tube Fittings

Used to connect, control, and terminate tubing in fluid systems, these stainless steel components ensure leak-proof and secure connections.

Features:

- Available in various grades, including 304 and 316 stainless steel.

- Designed for high-pressure systems.

- Provide precise and consistent connections.

Applications:

- Oil and Gas: Used in high-pressure fluid systems.

- Food and Beverage: For sanitary fluid transport.

- Pharmaceuticals: In sterile and cleanroom environments.

2. Stainless Steel Pipe Fittings

Pipe fittings, often made from stainless steel alloys, join or terminate sections of piping, allowing for direction changes and system branching.

Types of Pipe Fittings:

- Elbows: Change the direction of flow.

- Tees: Split or combine fluid flow.

- Reducers: Connect pipes of different diameters.

- Caps: Seal pipe ends.

Applications:

- Chemical Processing: For handling corrosive chemicals.

- Power Plants: In steam and water pipelines.

- Water Treatment: In systems exposed to chlorine and other chemicals.

3. Stainless Steel Forged Fittings

Forged fittings are made by shaping stainless steel alloys under high pressure, resulting in superior strength and good corrosion resistance.

Advantages:

- High-pressure and temperature tolerance.

- Greater mechanical strength than cast or machined fittings.

Applications:

- Marine Engineering: Handles saltwater environments.

- Oil Refineries: Used in high-temperature systems.

- Construction: For structural applications requiring robustness.

Benefits of Stainless Steel Fittings

1. Long-Term Durability

Stainless steel alloys exhibit excellent corrosion resistance properties, ensuring fittings last for years with minimal maintenance.

2. Leak-Proof Connections

Precision manufacturing of stainless steel components ensures tight seals, reducing the risk of leaks and system failures.

3. Versatility

Suitable for various industrial processes, stainless steel components transport corrosive chemicals and ensure hygiene in food production.

4. Sustainability

Stainless steel alloys are 100% recyclable, making them an environmentally friendly choice for industries.

Key Considerations for Selecting Stainless Steel Fittings

- Material Grade:

- 304 Stainless Steel: Ideal for general-purpose applications.

- 316 Stainless Steel: Offers superior corrosion resistance, particularly in marine and chemical environments.

- Operating Conditions:

- Consider the pressure, temperature, and type of fluids involved.

- Fitting Type:

- Choose the appropriate fitting type (tube, pipe, or forged) based on your system’s needs.

- Compliance with Standards:

- Ensure fittings meet international standards such as ASME, ASTM, or ISO.

- Supplier Reputation:

- Work with suppliers offering certified and high-quality products with reliable customer support.

Industries Using Stainless Steel Fittings

1. Oil and Gas

- Applications: High-pressure pipelines, offshore platforms.

- Benefits: Corrosion resistance and reliability under extreme conditions.

2. Food and Beverage

- Applications: Transport of liquids and gases in sanitary environments.

- Benefits: Hygienic and easy to clean.

3. Pharmaceuticals

- Applications: Sterile fluid systems and cleanrooms.

- Benefits: Maintains sterility and prevents contamination.

4. Chemical Processing

- Applications: Handling corrosive substances and high-temperature fluids.

- Benefits: Ensures safety and durability in harsh environments.

Conclusion

Stainless steel tube and pipe fittings are indispensable for industries demanding high performance, reliability, and durability. From sanitary applications in food and beverage to high-pressure systems in oil and gas, stainless steel fittings provide unmatched benefits. By choosing the right type and grade, industries can ensure efficiency, safety, and long-term value.

Need premium stainless steel fittings for your project? Contact us today to explore our extensive range of high-quality stainless steel products tailored to your needs!

FAQ's

Need Help?

We're Here for You!

Feel free to contact us any time. we will get back to you as soon as we can!

Ask Anything

Stainless steel tube fittings offer good corrosion resistance and durability, making them ideal for high-pressure applications in corrosive environments.

Forged fittings, made from stainless steel alloys, are stronger and more durable due to the forging process, which enhances the material’s corrosion resistance properties, making them suitable for high-stress applications.

Grade 316 stainless steel, known for its excellent corrosion resistance properties, is the preferred choice for chemical processing due to its ability to withstand chlorides and corrosive substances.